DYNAMIC SCHEDULING CONNECTED TO MACHINES

Innovations Awards

Information

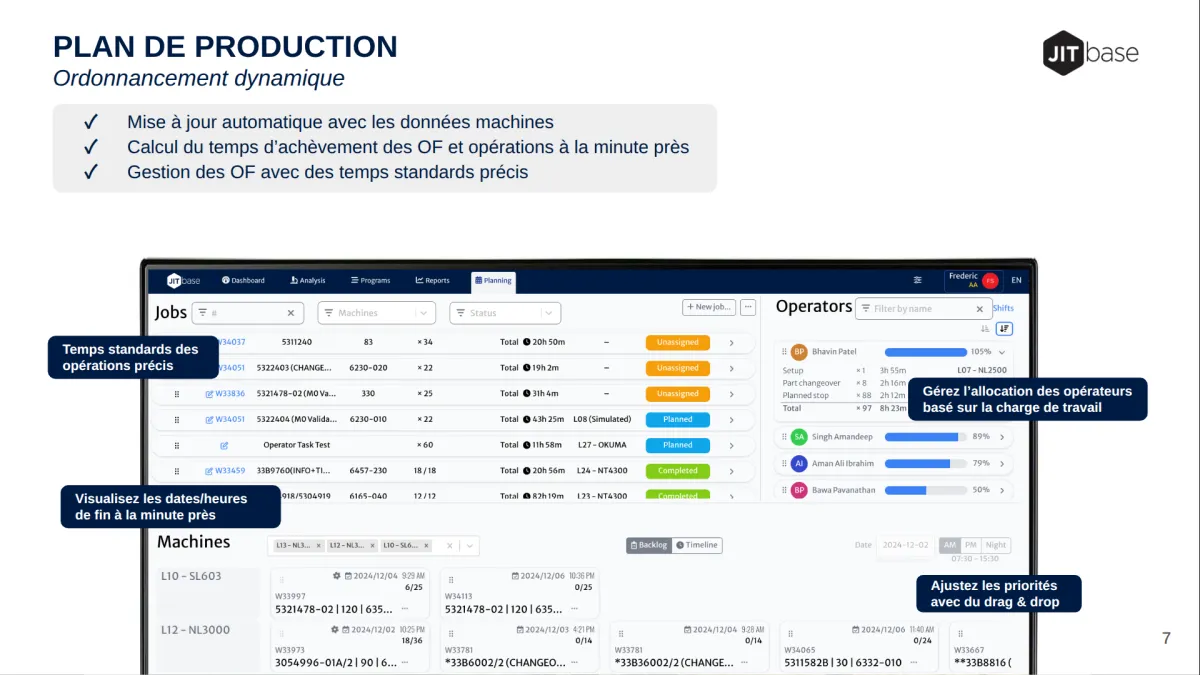

JITbase's dynamic scheduling solution continuously generates and adjusts the production plan based on real shop floor conditions. Unlike traditional approaches relying on static ERP or Excel schedules, JITbase connects production planning directly to real-time execution data to deliver a truly executable schedule.

The system takes into account machine capacities, operator availability, standard times, and industrial constraints, and automatically recalculates the plan whenever a disruption occurs (delays, breakdowns, operator absence, priority changes). The production schedule remains continuously synchronized with the actual state of the shop floor, without manual rework.

This approach enables production teams to shift from reactive planning to dynamic and anticipative control. Supervisors gain a clear, shared view of short-term production priorities, can immediately assess the impact of disturbances, and secure delivery commitments. By directly linking scheduling with real-time execution, JITbase delivers measurable improvements in industrial performance, schedule reliability, and operational responsiveness.