GIGA LASER NEXT

Innovations Awards

Information

Automotive manufacturers face market volatility, limited floor space, and pressure to cut costs through greater multi-part integration. As multi part hot stamped door rings spread, 3D laser cutting often becomes the bottleneck to meet 20–30 s takt times. Single head cartesian machines need multiple stations and large layouts, while robot systems enable multi head cutting but are slower, require more heads, and deliver lower OEE.

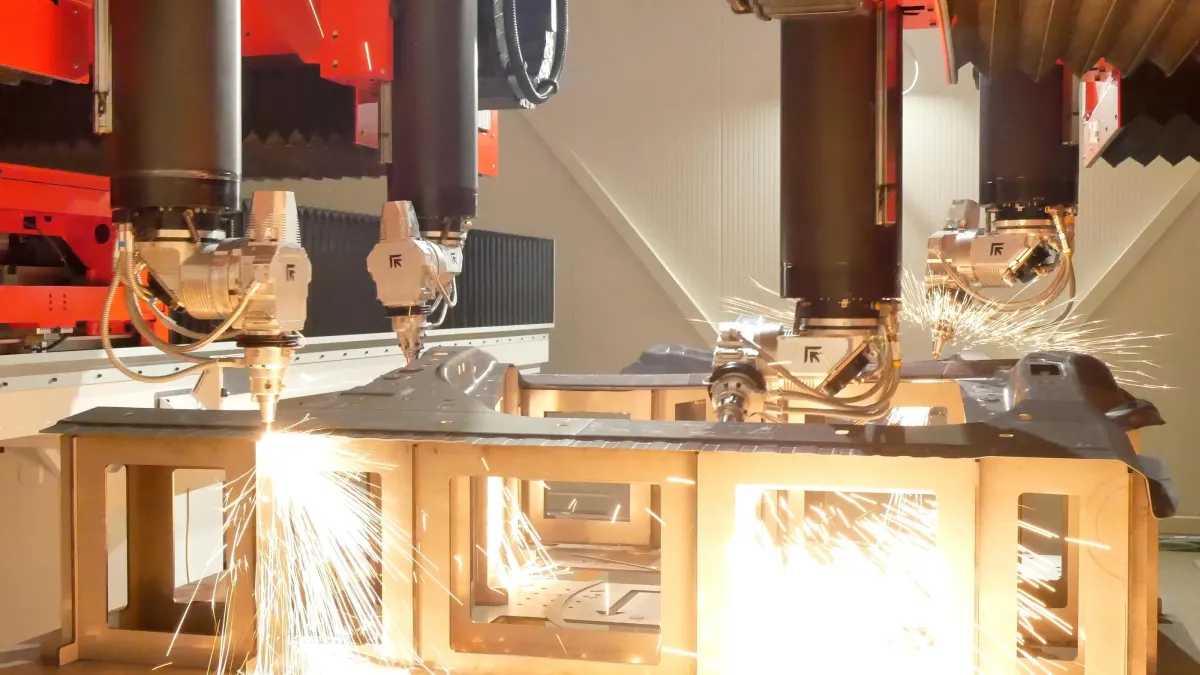

Giga Laser Next is the first 3D laser system that brings cartesian dynamics, precision, and robustness to a synchronized four head configuration cutting the same part at once. It integrates into a fully automated line with material handling, in line quality inspection, and direct flow from stamping to assembly.

Results at OEMs and Tier1s show +280% productivity per square meter and −75% cutting stations and changeover time versus traditional technologies, increasing throughput density while simplifying logistics. In production, it achieves the output of over four single head machines while using one cutting station per part instead of four, reducing setup, maintenance, WIP, fixtures, and supervisory labor.

Giga Laser Next turns 3D laser cutting from a bottleneck into a strategic, automated operation that sets a new benchmark for space time efficiency in body in white.