LVC

Produits

Information

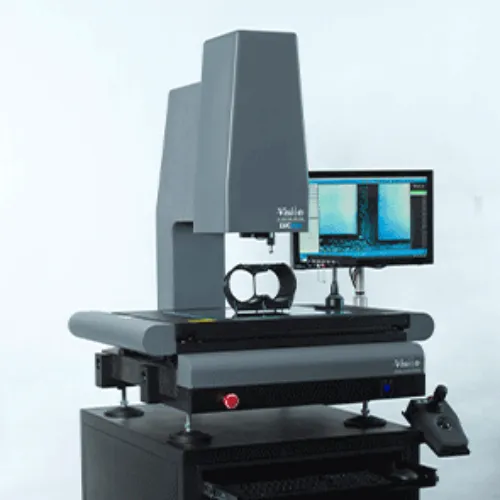

High Capacity CNC Video Measuring System Measuring accuracy (x, y) 2.5 (7.32L/1000) μm* encoder resolution 1 μm LVC400 is a fully automated 3-axis video measuring system with the power and flexibility to meet the most demanding requirements. It is ideal for measuring large or multiple small components quickly, easily and accurately. • Measuring range 400mm x 300mm x200mm • 6-position motorized zoom for automatic magnification change in measuring programs • 3D probe option for measuring complex features and 3D shapes, such as cylinders, cones and spheres. • 80x-300x Magnification Range on 63.5cm Monitor • Excellent Video Image with 5MP USB3.0 Video Camera • Intuitive M3 Software Provides Ease of Use • Granite Base for Increased Stability and Measurement Accuracy Automated 3-Axis Measurements Lengthy measurement procedures are often a major problem for manufacturers. Reducing measurement time, without compromising product quality, is a key factor in the continuous improvement of the manufacturing process. The LVC400 has the power and flexibility to meet the most demanding measurement needs and is suitable for industrial applications such as precision machining, molding, plastics, electronics, and medical and pharmaceutical devices.

Field of Application:

Ideal for a wide range of applications including precision engineering, molding, plastics, electronics, and medical and pharmaceutical device manufacturing. It allows you to perform automated measurements of components requiring a change in magnification. These changes can be included in your programming to avoid any stoppage in your measurement routines. Allows you to measure as many components as you can fit on the measurement stage by palletizing system. Offers you fully automated 3-axis measurement, saving you time and reducing your production costs.

Technical document

Nomenclature

Instrumentation, analysis, measurement, control, vision

Topic

Production and maintenance

Working machine

Frequency: Continiously