BRAMP - Injection Plastic Moulds

Produits

Information

BRAMP is certified according:

NP EN ISO 9001:2015

IATF 16949:2016

NP EN ISO 14001:2015

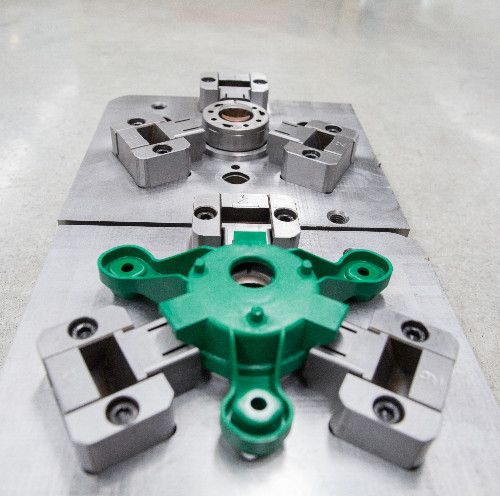

Moulds Production Dept.

- CNC machining centers (milling and turning);

- EDM machines;

- Laser welding;

- Auxiliary machinery;

This unit was created to assure the maintenance, repair, modification and refurbishment of the moulds of our customers but quickly evolved to the internal production of moulds;

Engineering and Commercial Dept.

- Designing and Development of new products / components supported by CAD/CAE software tools;

- Feasibility analyses and DFM studies of products developed by customers;

Rapid Prototyping Unit

- Prototypes manufacturing by FDM (ABS-M30, PC e PA12);

Metrology Dept. (internal capability for developing PPAPs)

- Dimensional control: scanner 3D, 3D coordinates machine and profile projector;

- Mechanical tests: Tensile machine;

- Humidity control; Color control;

- Durometer for hardness assessment;

- Others means of control usually available in this industry;

Technical sheet

Nomenclature

Plastics, rubber and composites