BRAMP - Injection Moulding Plastic Parts

Produits

Information

BRAMP is certified according:

NP EN ISO 9001:2015

IATF 16949:2016

NP EN ISO 14001:2015

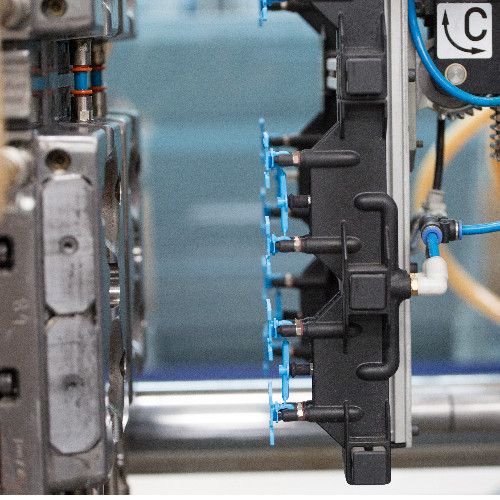

Production / Plastic Injection Dept.

- Plastic injection by mono and bi-material (2k);

- Capability of over injection, namely with metallic inserts;

- IML and IMD capabilities

- 67 injection machines with clamping forces from 15Ton up to 1.100Ton;

- 5 are bi injection machines;

- 80% of the total machines are ENGEL;

- Assembly lines for sets / products;

- Quality "wall"

Engineering and Commercial Dept.

- Designing and Development of new products / components supported by CAD/CAE software tools;

- Feasibility analyses and DFM studies of products developed by customers;

Rapid Prototyping Unit

- Prototypes manufacturing by FDM (ABS-M30, PC e PA12);

Metrology Dept. (internal capability for developing PPAPs)

- Dimensional control: scanner 3D, 3D coordinates machine and profile projector;

- Mechanical tests: Tensile machine;

- Humidity control; Color control;

- Durometer for hardness assessment;

- Others means of control usually available in this industry;

Technical sheet

Nomenclature

Plastics, rubber and composites