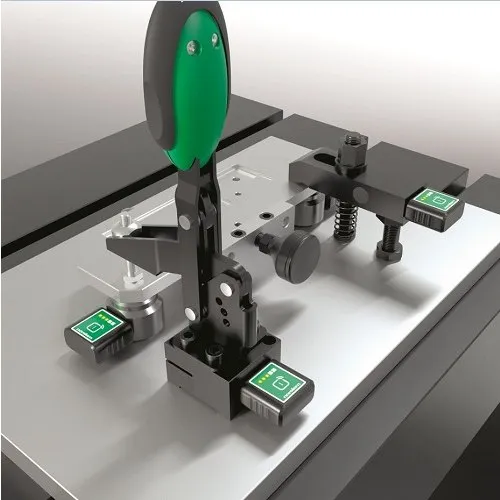

Clamping connected

Novelties

Information

With the growing prominence of the Internet of Things (IoT) and Industry 4.0, modern workshops are quickly transforming

into smart and connected environments.

To easily verify clamping and stops before machining with ergonomic and intuitive implementation, take advantage

of this technology.

• Intuitive setup: Connected products have simplified settings, allowing

for intuitive assembly. This optimizes installation speed, reduces

mistakes, and makes it user-friendly, even for those unfamiliar with it.

• Optimised quality: Connected products ensure that every part is

machined precisely, adhering to strict tolerances, which reduces the

number of rejects and the costs associated with re-machining.

• Wireless operation: Components install and connect without any

wiring.

• Resistant to cooling lubricants: Connected products have an IP64

protection rating, suitable for machining with cooling.

• Increased productivity: By reducing machining errors, workshops

can speed up their production without sacrificing quality.

• Cost reduction: Wasted materials, lost time. Connected products

minimize these errors.

• Proactive maintenance: These products can also signal wear,

anomalies, or any maintenance needs, allowing for anticipation of

potential problems.

• Easier training and assistance: Connected products can be linked

to a computer system providing real-time feedback to operators

throughout the machining process.

Verifying clamping and stops represents a major advancement

in the world of machining. It offers superior quality assurance,

but also increased efficiency, reduced costs, and better overall

workshop management. In an industry where precision and

efficiency are crucial, these products represent the future.

Brand

norelem