Cémentation Basse Pression

Novelties

Information

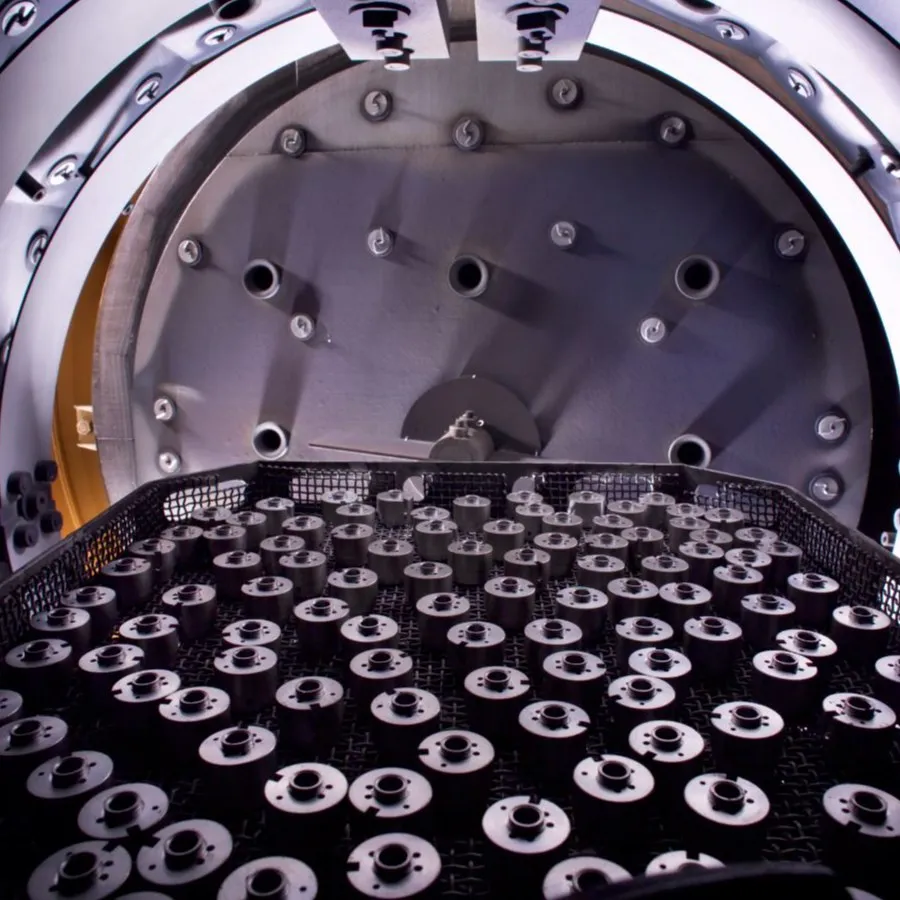

Low Pressure Carburising is a case hardening process carried out in a vacuum furnace, using gaseous hydrocarbons at very low pressure and high temperature to obtain a hardened surface layer of tempered martensite and a hard core. The treatment is used to increase the wear resistance and endurance of components.

Benefits

High undersurface hardness compared to conventional case-hardened parts.

Faster cycle times.

Parts can be case-hardened between 930 and 1000°C.

Penetration of carbon into deep blind holes gives uniform hardness across the profile.

Case hardening of small holes and blind holes.

No need to clean the part after heat treatment if combined with high-pressure gas quenching.

Improved mechanical properties thanks to the absence of intergranular oxidation, with improved fatigue resistance.

Dimensional control - low deformation, predictable and reproducible

Environmentally friendly because vacuum process

Applications

Low pressure carburising is used in many market sectors, including the automotive and aerospace industries, on a wide range of components such as transmission gears, pinions, shafts, fuel injectors, etc., which require a uniform carburised layer on all surfaces of the part, with minimal dimensional deformation. Combined with high-pressure gas quenching, the process produces a very clean surface, eliminating the requirement for subsequent cleaning of the part after heat treatment.